Micro Etching Systems

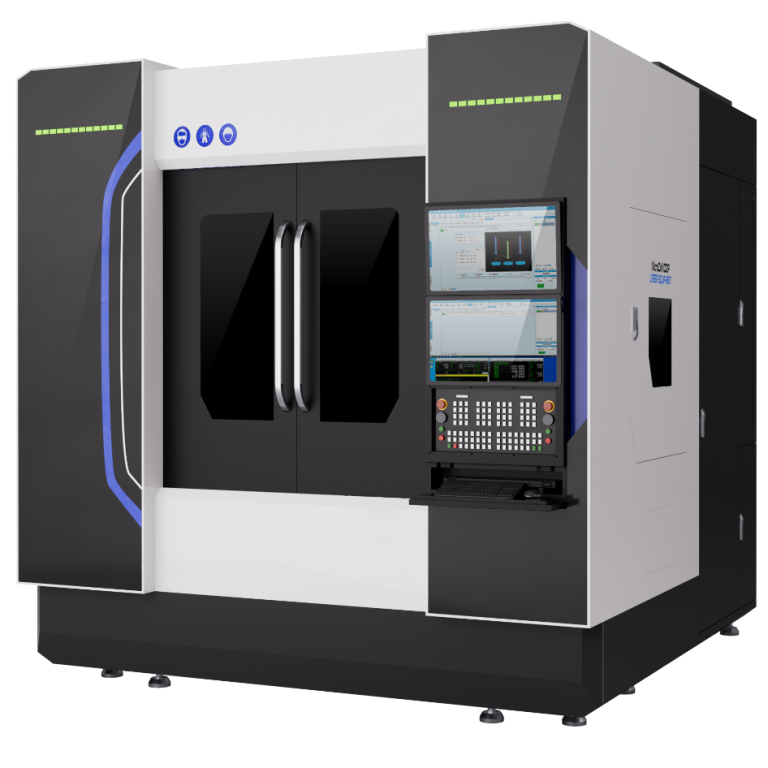

Five-Axis Linkage Etching System

Micro Etch 80LM

This system utilizes a high-power pulsed laser as the processing light source. By integrating model reconstruction and a five-axis linkage system combining mechanical axes with a galvanometer, it enables precision surface etching on large rotary surfaces, three-dimensional micro-curved surfaces, and two-dimensional planes. This system offers exceptional advantages in high-efficiency, high-precision etching on three-dimensional surfaces.

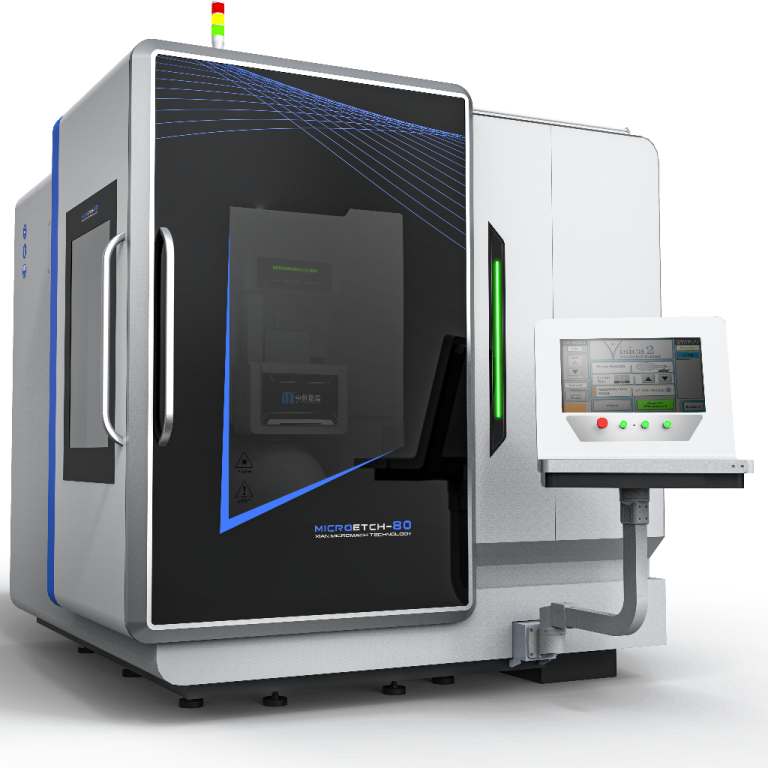

Micro Etching System

Micro Etch 80

This system utilizes a high-power ultrafast laser as the processing light source and is equipped with an AC cradle for part clamping. It is specifically designed for precision etching of functional microstructures on complex three-dimensional curved surfaces. With features such as five-axis simultaneous linkage, surface model segmentation and stitching, and parallel light projection, the system enables advanced 3D model processing, allowing for surface etching on non-developable 3D curved surfaces with high precision and efficiency.

Large Scale 3D Surface Etching System

Micro Etch 200L

This system utilizes a high-power ultrafast laser as the processing light source. Built upon a three-axis fixed-gantry mainframe, it is equipped with a core optical dual-swing-axis module, making it ideal for precision etching of functional microstructures on large, complex 3D curved surfaces.