Micro Drilling Systems

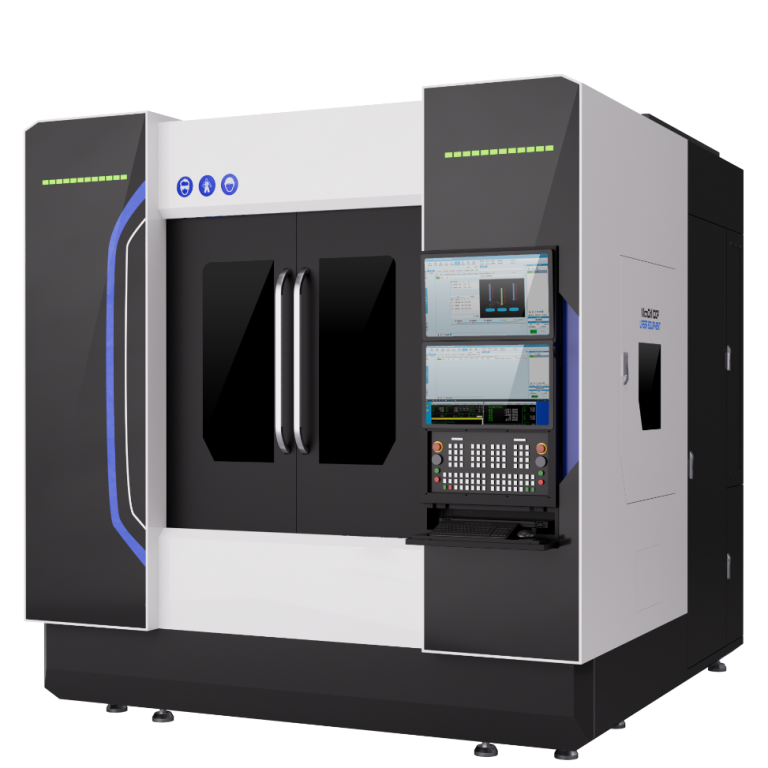

Long and Short Pulse Composite

Micro Drill 90

This system is an independently developed product based on five-axis laser processing technology. It uses a long and short pulse composite process to achieve high efficiency micro hole processing of cylindrical and special-shaped holes on the surfaces of various metals, non-metals, and composite materials.

Micro Drilling System

Micro Drill 80

This system utilizes a high-power ultrashort pulse laser as the processing light source, equipped with a scanning module. It is specifically designed for ultra precise cold processing of curved and complex shaped components.

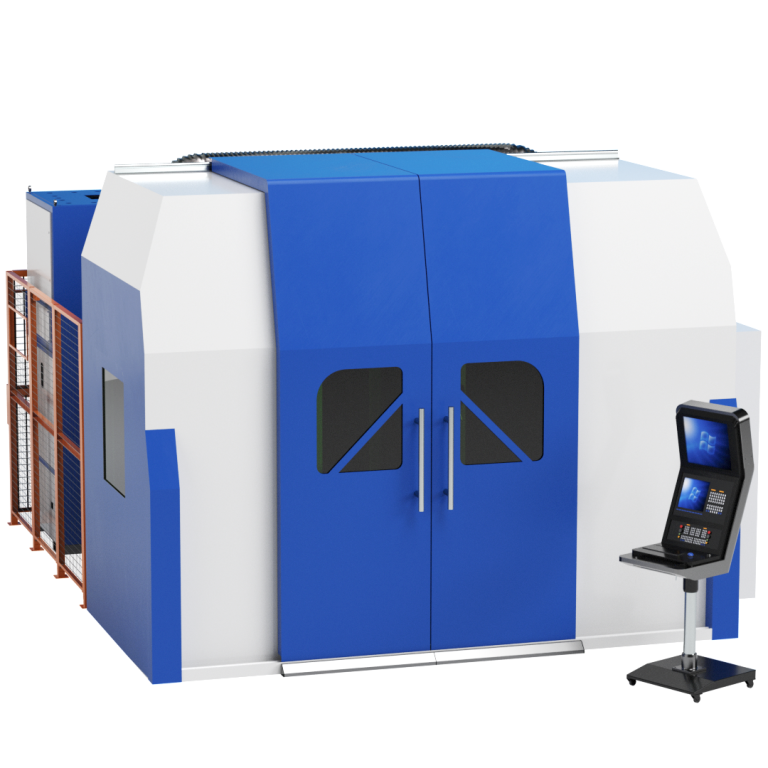

Dual Station Drilling System

Micro Drill 40P

This system utilizes a high-power ultrashort pulse laser as the processing light source. It employs a dual-beam optical transmission module for beam splitting, adjustment, and delivery. Combined with a multifunctional high-speed scanning module and a dual-station machine system, it enables high-precision parallel processing of identical workpieces, improving overall efficiency by more than 70%.

High Speed Micro Drilling System

Speedy Drill 100H / 200L

This system utilizes a high-power QCW (Quasi-Continuous Wave) fiber laser as the light source and is equipped with a six-axis and five-axis linkage motion control system. By integrating adaptive positioning technology and real-time precise laser parameter control, it enables high-precision cutting and drilling of circular holes, airfoil-shaped holes, and complex surface trajectories.

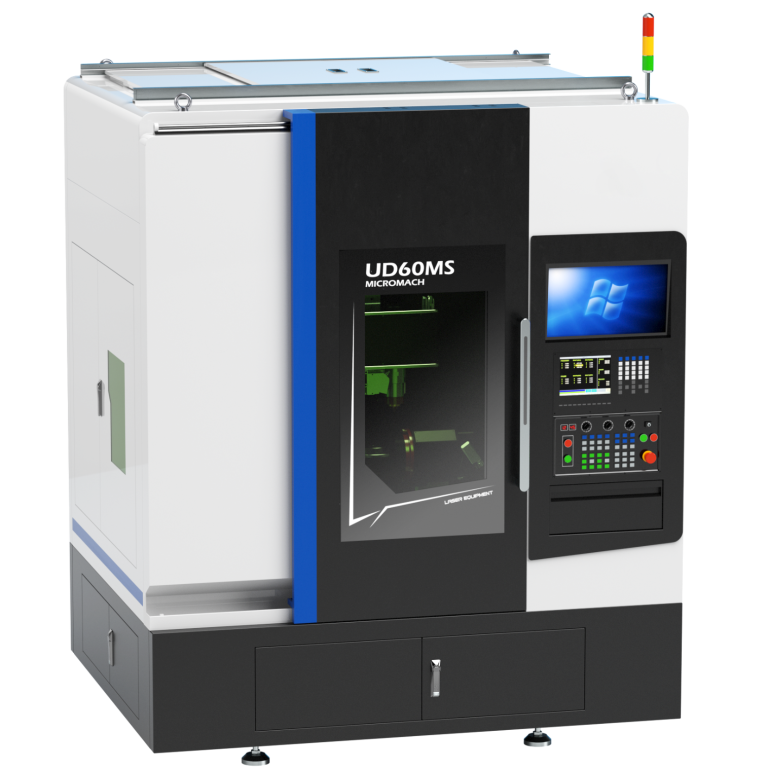

Ultra Precision Micro Drilling System

Ultraprecise Drill 60MS

The UD Series is designed for micron-level ultraprecision microstructure processing. Utilizing a modular design concept, it is adaptable to various application scenarios. By integrating different configuration combinations, the system enables high-precision laser micro hole drilling, etching, cutting, and turning, providing versatile and efficient processing capabilities.