Composite Beam Scanning Technology

High-Speed Precision Shaping for Complex Microstructures

Experience next-level manufacturing with our advanced Composite Beam Scanning System.

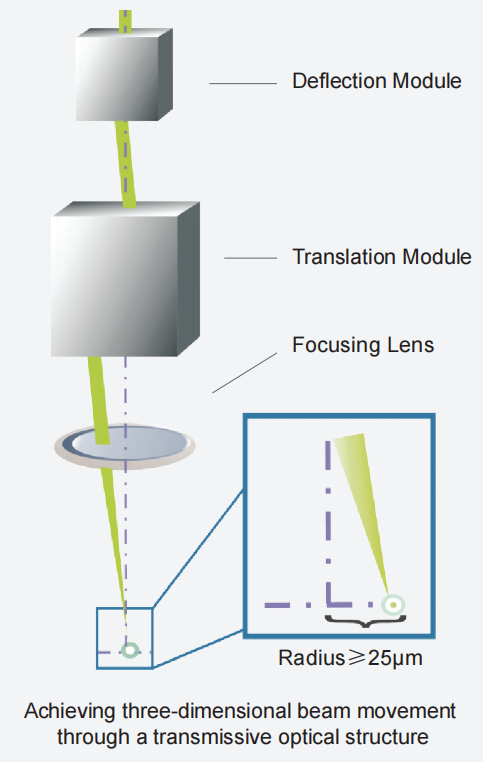

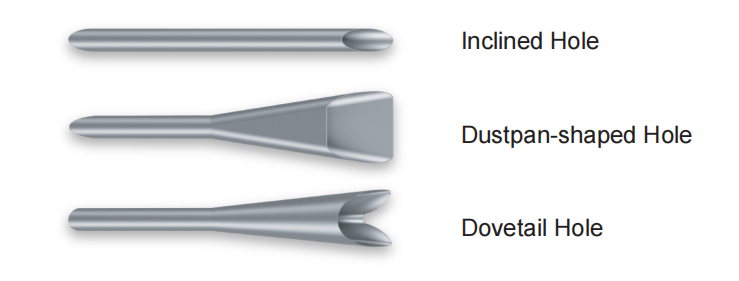

This three-dimensional programmable beam scanning technology enables high-speed, ultra-precise shaping of intricate microstructures—including deep cavities, inclined or curved holes, and special side profiles such as dovetail or dustpan shapes.

Powered by a highly stable, transmissive optical structure and intelligent beam control modules, this system overcomes traditional limitations in laser micromachining, significantly expanding the possibilities of modern component design.

Key Features & Advantages

· 3D Programmable Scanning Module for dynamic beam shaping

· ±0.002 mm scanning accuracy for sub-micron level control

· Supports complex holes like inclined, dovetail, and racetrack shapes

· Max taper control up to -6°, fully programmable

· Ideal for small-scale components requiring high aspect ratios and structural precision

· Rotation speed up to 9000 RPM for high-efficiency production

Typical Applications

· High-efficiency hole drilling in turbine blades

· Machining cooling holes with side profile control

· Complex cavity shaping in aerospace and energy sectors