Applications

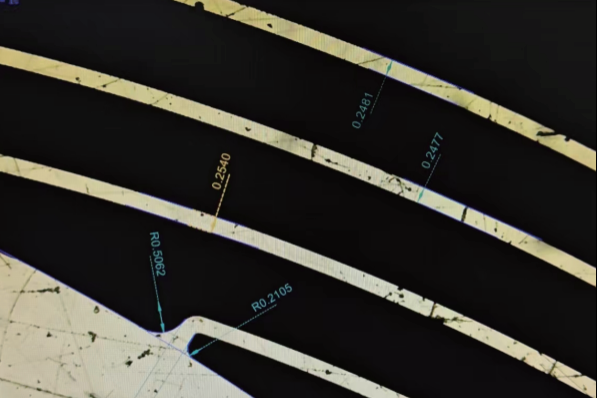

Ultrafast Laser Precision Drilling

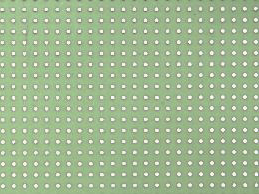

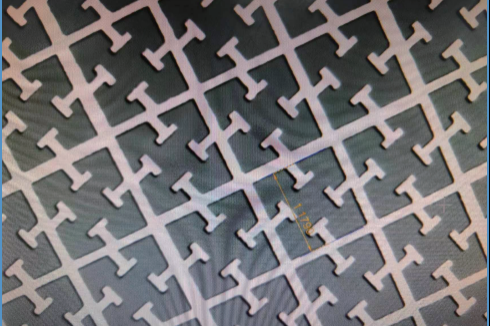

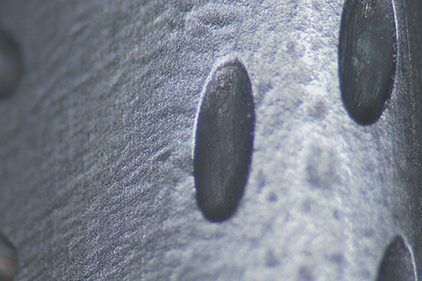

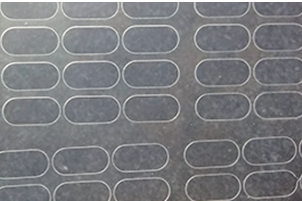

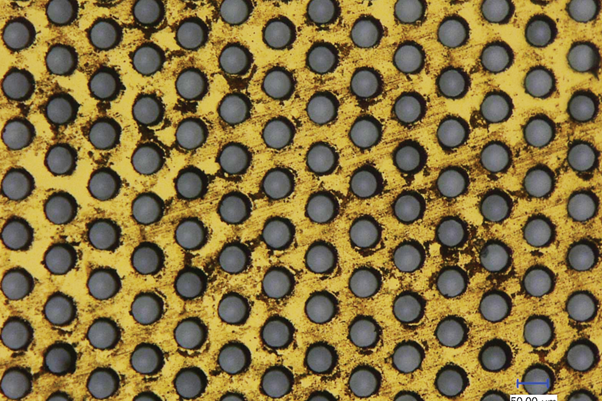

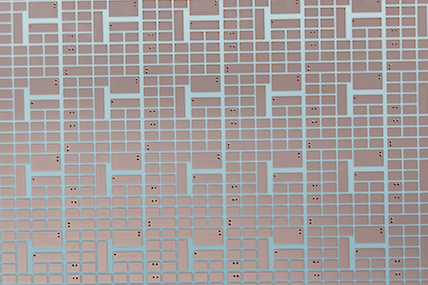

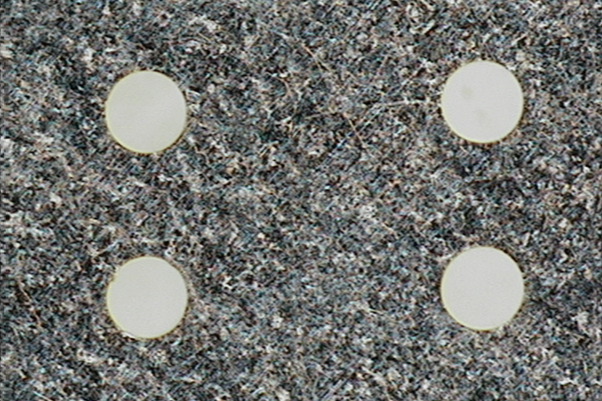

High-quality processing of various air film holes such as cylindrical holes, square holes, and special-shaped holes, as well as complex curved surface parts with multiple holes. High-efficiency and high-precision processing of large quantities of holes for parts like flow control plates

and grids.

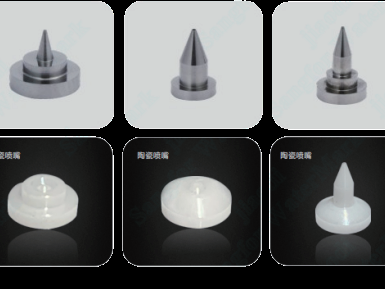

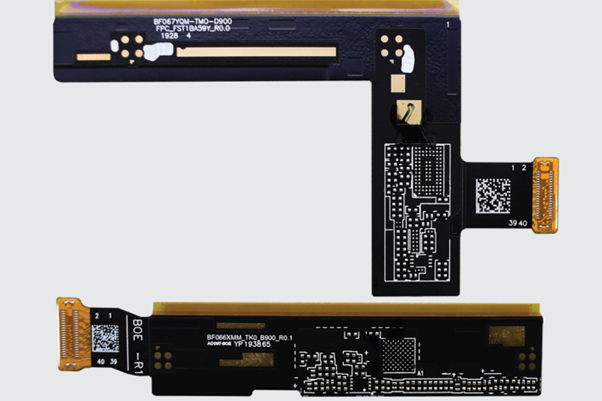

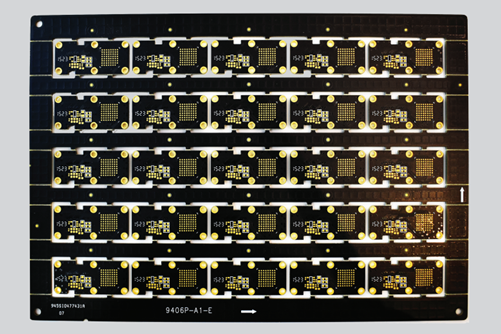

Micron-level inverted cone injection holes for fuel injectors in the automotive industry. High-quality and efficient drilling for flexible ceramics, PCBs, FPCs, sapphire, glass, IC substrates, and other electronic components.

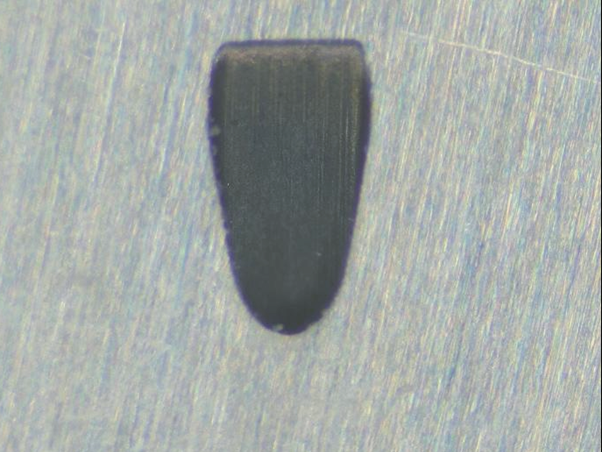

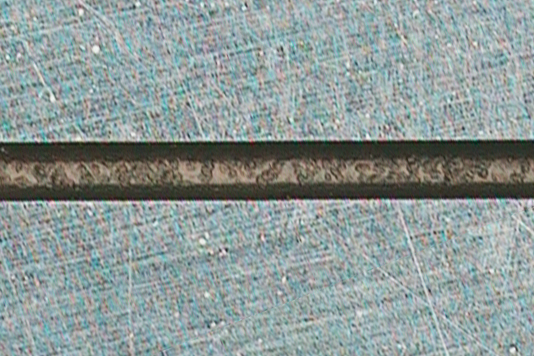

Shaped Slot Hole for Spinnerets

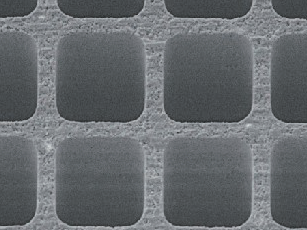

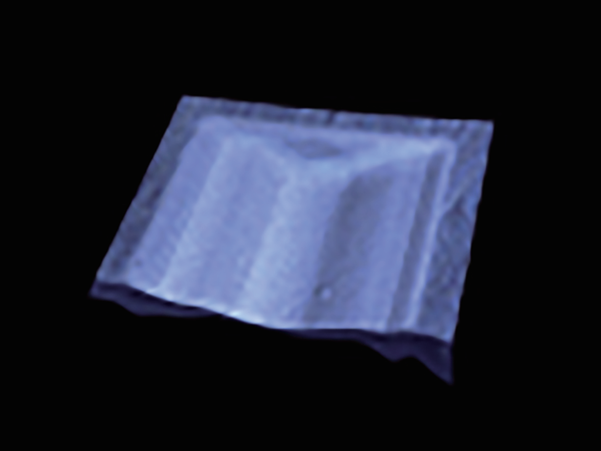

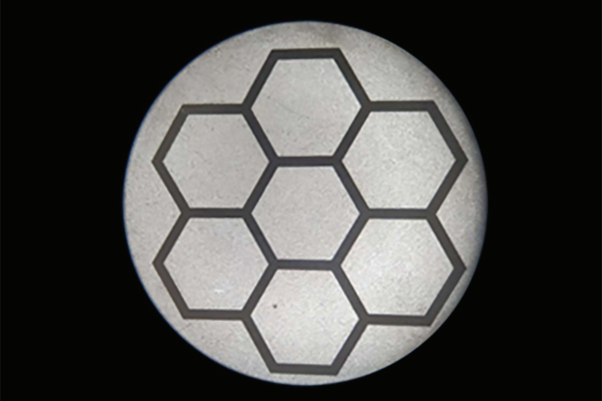

Probe Card Square Hole

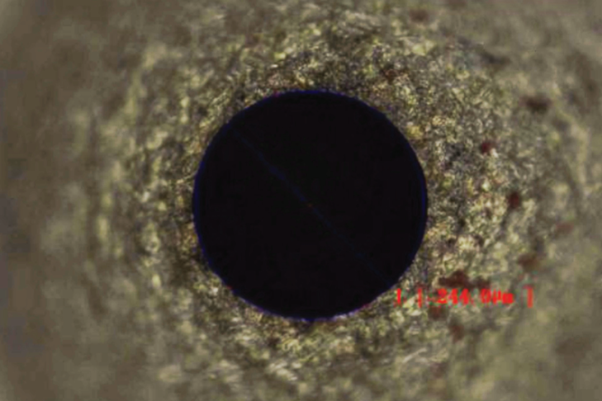

Micro Hole for Dispensing Nozzles

Ceramic Needle Hole Drilling

HTCC Green Ceramic Drilling

Automotive Flow Guide Micro Holes

Glass Drilling

Shaped Hole in High Temperature Alloys

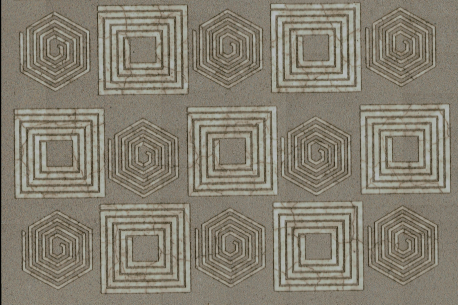

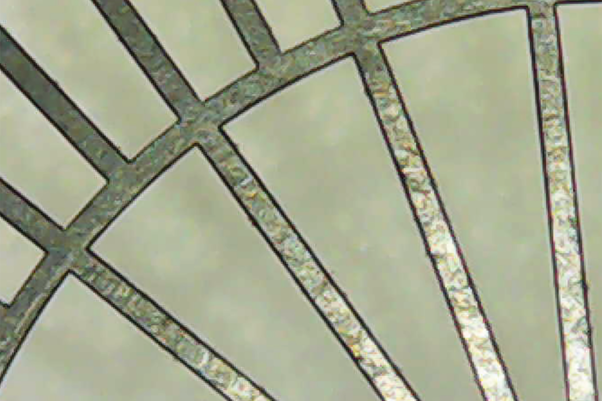

Ultrafast Laser Precision Etching

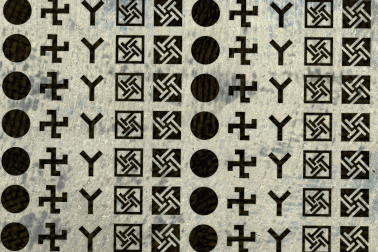

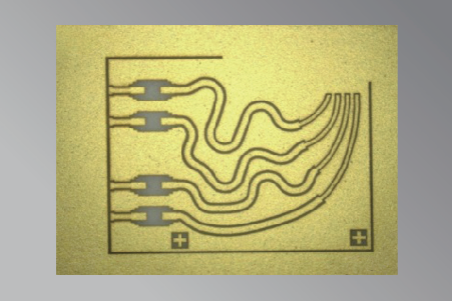

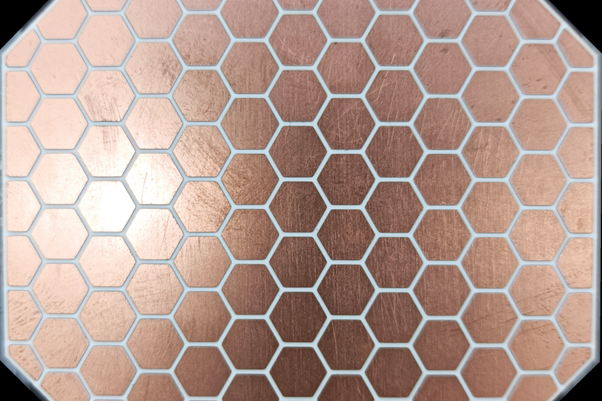

Ultra-Precision Etching of Complex Microstructures: Including filter membranes and other intricate designs.

High-Accuracy Segmented Etching of Resonant Structures on Large Curved Surface Components. Precision Etching of Complex Micro-Grooves in Ceramic Cores.

Ultra-Fine Etching of Hard and Brittle Materials: Such as ceramics and sapphire for the electronics industry.

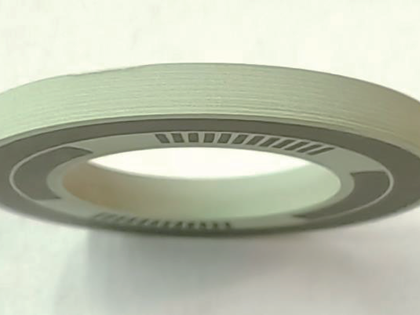

Liquid Metal Bearing

Ultra Fine Etching of Amber

Etching of Thin Hard Brittle Material plates

Etching on The Painted Surface of Stone

Tungsten Carbide Etching

CBN Etching

Filter Thin Plate Etching

Light Guide Plate Mold Etching

Ultrafast Laser Precision Cutting

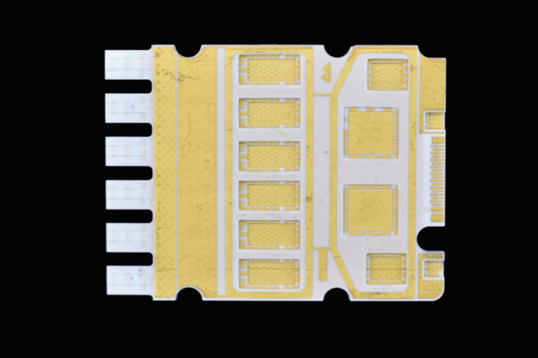

High-Precision, Non-Ablative Cutting of Complex Patterns for Electronic and Communication Components: Including traveling wave tubes, leads, and other intricate parts.

High-Quality, High-Efficiency Cutting for Electronic Materials: Such as glass, sapphire cover plates, alumina, zirconia, ceramic substrates, silicon wafers, and LED chips.

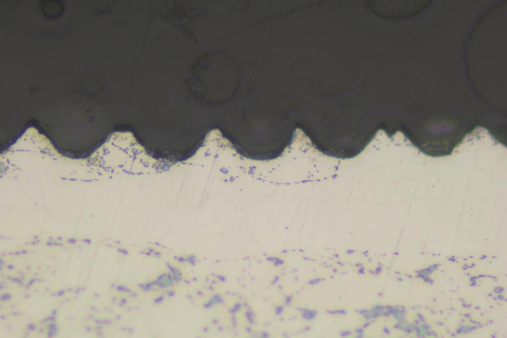

High-Precision,High-Consistency Cutting for Medical Applications: Including thin-walled tubing such as cardiac stents.

Fine Cutting of High-Temperature Alloys

Jet Component Cutting

Ultra-Fine Cutting of Tungsten Materials

HTCC Thick Green Ceramic Cutting

Precision Turning of Probe Pins

Copper Foil Cutting

LTCC Cutting

Glass and Sapphire Cutting

Aerospace

Coated Complex Hole Machining

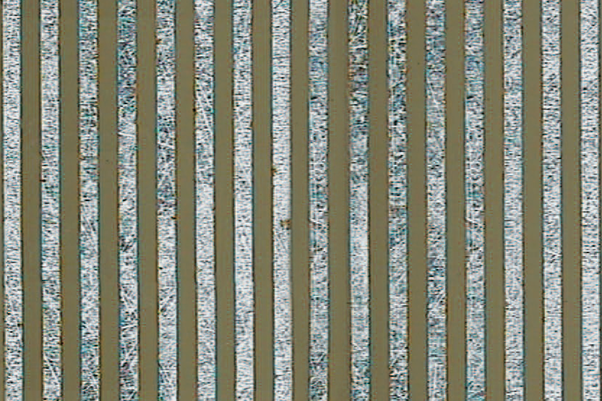

Massive Array Hole Machining for Aerospace Molybdenum Materials

Aerospace Titanium Material Drilling

Aerospace Titanium Material Etching

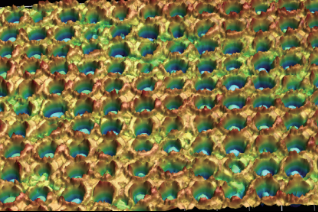

Complex Surface Microstructure

Complex Curved Surface Microstructures

Complex Curved Surface Microstructures

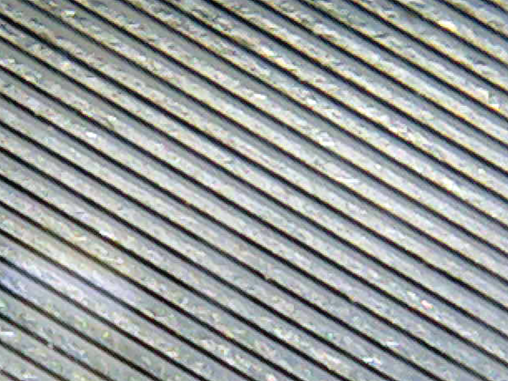

Aluminum Alloy Surface Roughening

Microstructure Photograph

of Surface Roughening on

Superalloy

Micro-Groove Processing

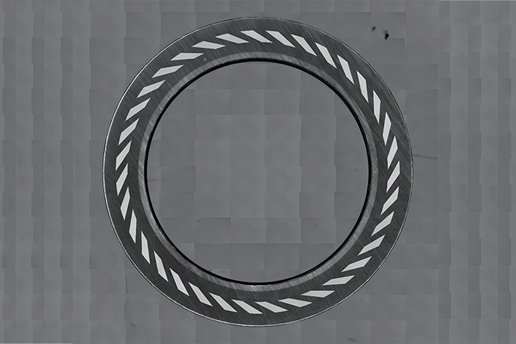

Precision Cutting of Sealing Components

Coated Inclined Hole Machining

Electronics Industry

Thick Glass Cutting

Ultra-Thin Glass Cutting

Molybdenum Material Cutting

Lead Cutting

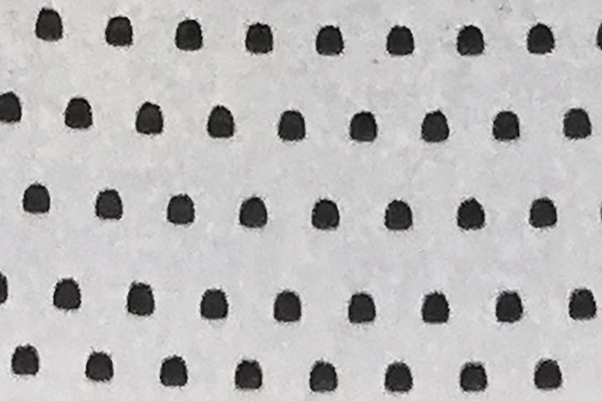

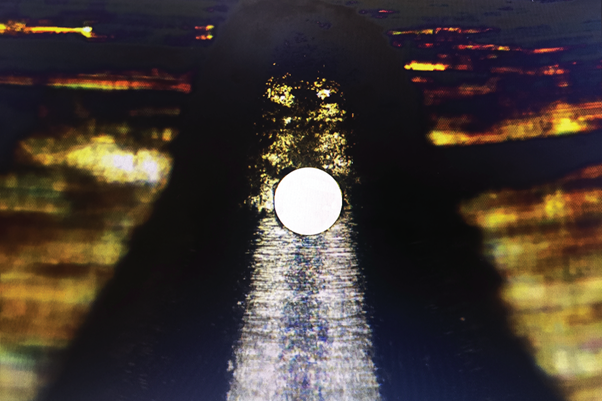

Micro-Perforated Stainless Steel Plate Drilling

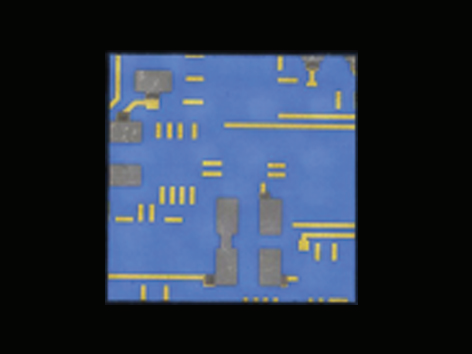

Gold-Plated Ceramic Etching

LTCC Cutting

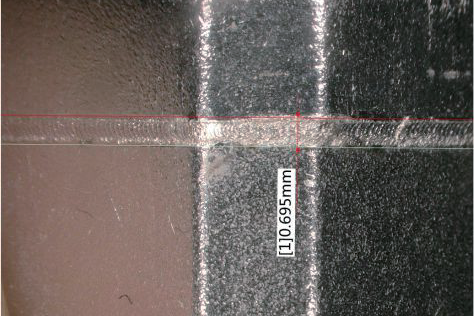

Ceramic Panel Scribing

Silver-Plated Ceramic Scribing

Alumina Cutting

FPC Cutting

PCB Cutting

Automotive

Precision Welding of Aluminum Housings for Automotive Cameras

Fuel Injector Nozzle Drilling

Fuel Injector Orifice Plate Drilling

Medical Devices

Stainless Steel Micro Spring Cutting

Stainless Steel Micro Gear Cutting

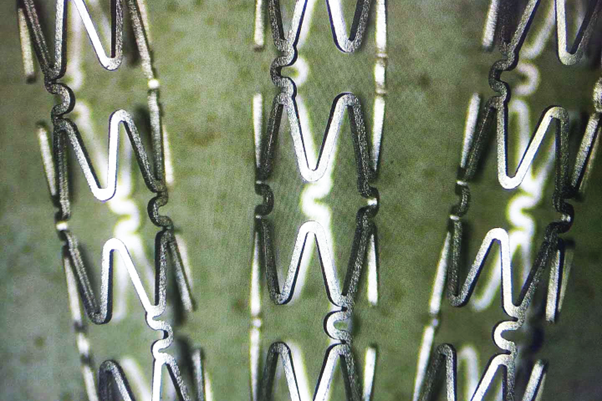

Cardiac Stent Cutting

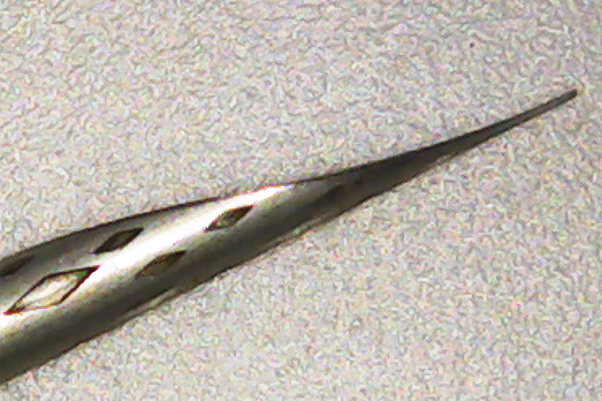

Puncture Needle Cutting

Cutting Tools

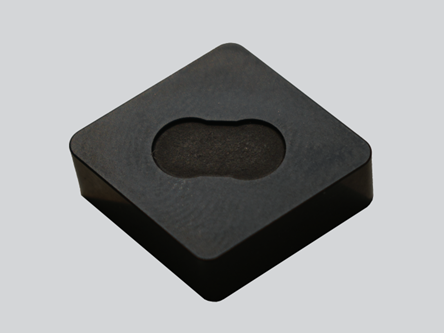

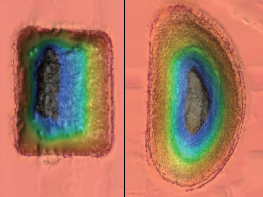

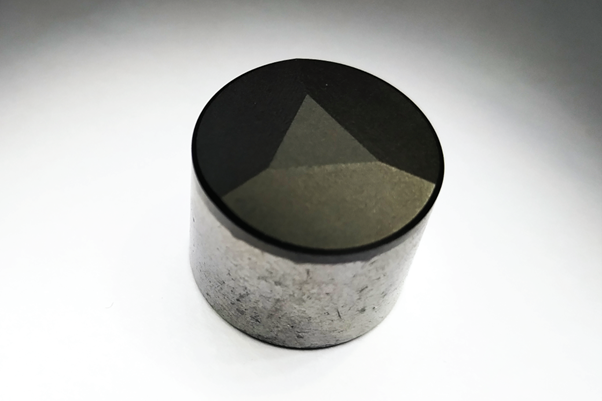

PCD Tool Etching

Carbide Etching

CBN Etching

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.