Inspection Systems

Cooling Hole Inspection System

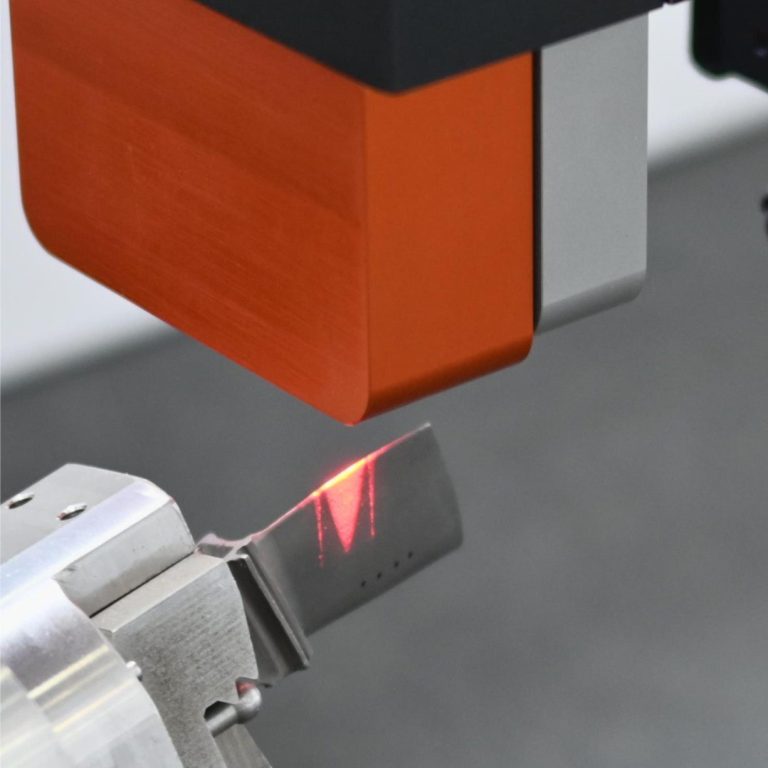

Panther Eye M1000

Panther-Eye M1000 is a specialized inspection system designed for the cooling holes of aero-engine blades. It utilizes industry-leading optical AI confocal fusion technology and white light interferometry to achieve high-precision measurement of various cooling holes. The system measures key parameters such as hole diameter, position accuracy, angle, hole spacing, and surface roughness. It is ideal for quality evaluation after cooling hole processing and supports integration with automated production lines, enabling fully automated intelligent inspection. With simple and efficient operation, the Panther-Eye M1000 is the premier solution for cooling hole inspection.

Cooling Hole Inspection Case

Supports measurement of hole diameter, positional accuracy, angle and permeability for cooling holes.

Cooling Hole Inspecition Case

Capable of measuring hole geometry and contour parameters for both shaped and conical holes, enabling rapid high precision measurement.

Technical Specifications Overview

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.